Product Description

Shortening dough: When making dough, the dough is packed with shortening butter (shortening butter has specially sold products, can also be a mixture of Marchilene and butter), by wrapping in shortening butter, the dough can achieve the effect of crisp layering, the taste is very crisp.

Product Application of the dough sheeter

Suitable for flattening and stretching pastry, Danish bread, dough dough, croissant dough, dough pie, cookie dough, pie pastry, almond and pizza dough

Main Features of the dough sheeter

(1) the use of pastry, crisp cake, thousand layer crisp and so on. It can also be used for rolling dough.

(2) immersion design, low noise, easy to wear and prolong service life.

(3) using imported components and superior steel, the pressure wheel is treated with special treatment without sticking and scratching.

(4) the pressure wheel and scraper are professionally designed to make the face skin thinner to 1mm, with uniform thickness.

Machine composition

Main parts: Box + display board + BELT + safety rack.

Auxiliary: drum, scraper, left and right direction adjusting rod, thickness adjusting rod, dry powder box.

operation of the dough sheeter

1 put down the platform and safety protection on both sides, and turn on the power switch.

2 the air machine is reversing and confirming that the operation is stable, and the pressure roller clearance is adjusted to a reasonable value.

3. Place dough on the conveyor belt and roll it repeatedly. Adjust the roll gap once every time until the thickness of the dough reaches the ideal thickness.

4. Sprinkle a little flour on the surface during the rolling process, so that the working condition of the product will be greatly improved. The amount of flour will be determined according to the need.

The forward and reverse control rod is a long horizontal rod with a handle ball at both ends. When the conveyor belt is pressed down on the other side, the conveyor belt will move to the other side.

6. The thickness adjusting handle is close to the upper side. It can be adjusted when the positive and negative control lever is in the horizontal position. Press the red ball adjusting handle on the upper end of the handle and loosen the red ball locking adjusting disc.

Machine Parts

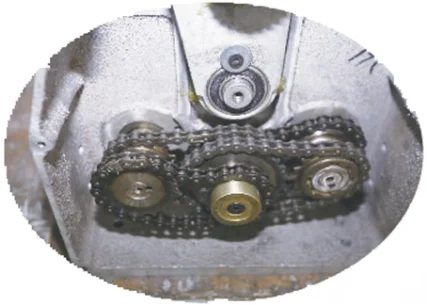

Change gear drive to chain drive to reduce attrition caused by gear friction.

Main Features

The use of mosaic scrapers is more convenient than screw fixed disassembly.

Machine Parts

Motor and rubber pads to enhance the shockproof function (no noise).

Main Features

The track bandwidth is 500 mm and the length is 2.2 meters. In order to ensure that the track does not deviate and prolong its service life, a track tightening adjusting device is provided. Adjustable length is 10cm

Because bearing is an easy and bad accessory, it changes the way of bearing installation and makes the disassembly simple. Apart from the screws, the bearing can be easily taken away, so that the PVC conveyor belt can be changed easily.

Safety measures in place, safety hood pulled up, track stop rotation, prevent accidents, ensure personal safety.

Maintenance and maintenance of the dough sheeter

(1) after work, the equipment is open to trial operation, and the equipment will be officially started after the equipment is ////confirm/i/i/i/ied.

(2) Rolled dough should not be too hard (such as frozen dough), one-time thinning should not be too large, otherwise it will affect the working stability and service life of the equipment.

When the dough thickness is more than 10 mm, it can be thinned by about 5 mm each time. When the dough thickness is between 5 mm and 10 mm, it decreases by about 2 mm each time. When the dough thickness is less than 5 mm, it decreases by about 1 mm each time.

(3) transport platform should not carry heavy load.

(4) After running for 40 hours, please re-tension the belt and chain to the appropriate position, so as not to drive slippery, chain off;

(5) After 80 hours of operation, please refuel the transmission parts such as sprocket and chain, and tighten the fasteners such as screw and nut to avoid damaging the parts.

(6) Keep clean and intact, bearing, belt, chain and other transmission parts can not be attached with flour, dust and other foreign bodies, in order to avoid burning out bearings or accelerating wear and tear parts;

(7) clean the machine before going to work everyday, please wipe it with a rag, but do not rinse it with water pipe.

(8) abnormal sound response is found to be shut down immediately.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Pre-Sales Service

1.Advice for equipment device

2.Customization is supplied depend on your demand

3.The voltage can be changed according to your choice

4.Relative market information and your inquiry is timely replied within 5 hours.

After-Sales Service

1. Whole life's technical consultant of the machine.

2.Site-repair is offered when it necessary

3.Spare parts are provided of some machines

4. 12 months warranty, lifelong service and technical support.

The FAQ of the dough sheeter

Q1.What Methods of Payment Are Acceptable?

1. Telegraphic Transfer (T/T): we accept 30% T/T deposit before production and 70% T/T Balance before shipment. 100% payment for sample orders.

2. Western Union: we accept 100% payment via the western union.

3. Letter of Credit (L/C): we accept 100% L/C irrevocable at sight.

Q2. What Is the Cost of Shipping?

Shipping cost is based on the following elements:

1.Number of packages 2. Gross Weight 3. Package CBM 4. Destination port

We can arrange shipping for you , if you have shipping agent in China , we can send goods to your warehouse .

Q3. How about the Delivery Time?

Some of the products are in stock at our warehouse, generally we need 3~5 days to change the plugs before the delivery. Regarding to the non-stock products, the lead time 15-30 days depends on your requirement on the product.

[VIP 1 Years] Rank:4

[VIP 1 Years] Rank:4 verified

verified